Cnc Drill Line Drawing

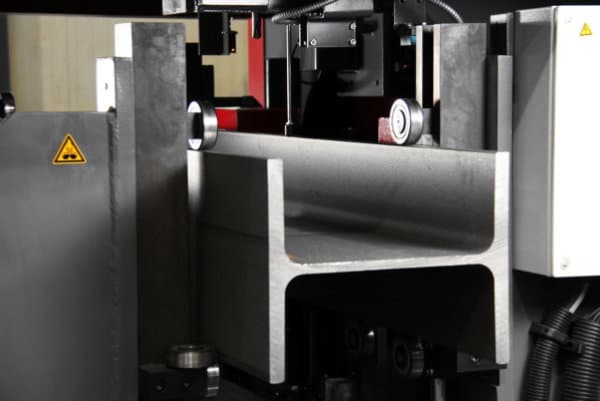

Voortman AccuMeasure Roller Feed measurement equipment offers saw measurement options. AccuMeasure provides complete handling versatility while offering a simple, streamlined CNC solution. This allows for both a drill and saw to be disassembled, which maximizes production.

Voortman's 24 Hour Tech Support Center can resolve 90% of support issues. However, there are 50+ Voortman field personnel stationed all over North and South America, Europe and Africa.